Aqua Silencer | Seminar Report for B.Tech Mechanical Students

Aqua Silencer | Seminar Report for B.Tech Mechanical Students

Air pollution is most important from the public health of view, because every individual person breaths approximately 22000 times a day, inhaling about 15 to 22 kg of air daily. Polluted air causes physical ill effect decides undesirable aesthetic and physiological effects. Air pollution can be defined as addition to our atmosphere of any material, which will have a dexterous effect on life upon our planet. The main pollutants contribute by automobile are carbon monoxide (CO), unburned hydrocarbon (UBHC), oxides of nitrogen (NOx) and Lead.

Automobiles are not the only sources of air pollution, other sources such as electric power generating stations, industrial and domestic fuel consumption, refuse burning, industrial processing etc. also contribute heavily to contamination of our environment so it is imperative that serious attempts should be made to conserve of our environment from degradation.

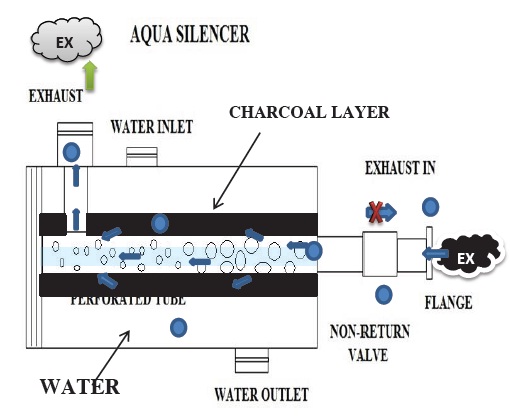

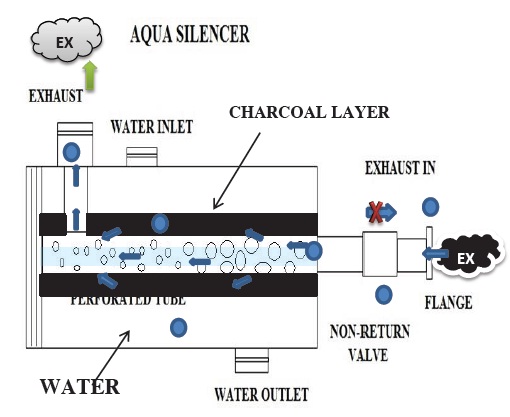

An Aqua Silencer is an attempt, in this direction, it is mainly dealing with control of emission and noise. An Aqua Silencer is fitted to the exhaust pipe of engine. Sound produced under water is less hearable than it produced in atmosphere. This mainly because of small sprockets in water molecules, which lowers its amplitude thus, lowers the sound level. Because of this property water is used in this silencer and hence its name AQUA SILENCER. The noise and smoke level is considerable less than the conventional silencer, it is cheaper, no need of catalytic converter and easy to install. It is imperative that serious attempts should be made to conserve earth’s environment from degradation. An aqua silencer is an attempt in this direction; it is mainly dealing with control of emission and noise.

INTRODUCTION

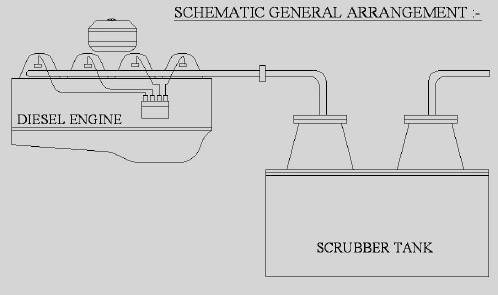

Diesel engines are playing a vital role in Road and sea transport, Agriculture, mining and many other industries. Considering the available fuel resources and the present technological development, Diesel fuel is evidently indispensable. In general, the consumption of fuel is an index for finding out the economic strength of any country. Inspire, we cannot ignore the harmful effects of the large mass of the burnt gases, which erodes the purity of our environment every day. It is especially so, in most developed countries like USA and EUROPE. While, constant research is going on to reduce the toxic content of diesel exhaust, the diesel power packs find the ever increasing applications and demand. This project is an attempt to reduce the toxic content of diesel exhaust, before it is emitted to the atmosphere.

This system can be safely used for diesel power packs which could be used in Inflammable atmospheres, such as refineries, chemical processing industries, open cast mines and other confined areas, which demands the need for diesel power packs. For achieving this toxic gases are to be reduced to acceptable limits before they are emitted out of this atmosphere, which otherwise will be hazardous and prone to accidents.

The principle involved is by bubbling the exhaust gas through the scrubber tank containing an alkaline solution, here the temperature of the gases is reduced, while most of the oxides of nitrogen in the exhaust are rendered non – toxic. The highly dangerous carbon monoxide is not such a menace in diesel exhaust, as it does not exceed 0.2 percent by volume, whereas in petrol engines the CO content may be as high as 10 percent. A lime stone container in the scrubber tank reduces the considerable percentage of sulphur – di – oxide presents in the exhaust.

The provision of suitable baffles in the scrubber tank aids the turbulence so that, thorough scrubbing take place. The bell-mouth solution, while reducing the back pressure. For measuring the contents of the exhaust gas, provisions are made to take samples between engine outlet and scrubber inlet and after the scrubber outlet before the gases are let out to the atmosphere. These sampling points enable us to measure the exhaust gas content before and after scrubbing. The difference is evaluated and effective control is initiated.

DESIGN CONSIDERATIONS

The exhaust gas contains carbon – di – oxide, sulphur – di – oxide, carbon monoxide and other oxides of nitrogen. At full load, the temperature of the exhaust gas will lay anywhere between 500°c to 700°c.

The pressure of the exhaust gas depends upon so many factors viz.

�� The design of exhaust gas manifold

�� Magnitude of valve overlaps

�� Engine speed

�� Number of cylinders

�� The length of the exhaust gas flow path etc.

The design of exhaust gas manifold is very important in case of high speed diesel engines. In order to maintain the exhaust gas pressure within the required limits, the exhaust gas manifold is designed so that, the gases, which come out of the cylinder flows very smoothly, before it is let out into the atmosphere.

This is absolutely essential in order to maintain the back pressure within safe limits, so that the engine can be kept at the optimum operating level. The back pressure, if it is allowed to exceed the pre-determined level, the effort on the part of the piston for scavenge is considerably increased and so power is lost in performing the above, so, the primary consideration when introducing any modification in exhaust system does not and shall not increase the back pressure which drastically affect the performance characteristics of an engine. To be more precise, the speed of the engine is affected for a given specific fuel consumption rate and so the combustion characteristics of an engine are all affected. As a net result of the combustion is not proper and complete which results in the increased impurities or unburnt gases. This principle against the purpose of introducing any system whose sole object is reducing the very toxic property of the exhaust gas.

So, it is implied that the introduction of any system reduces the toxic property of the exhaust gas, shall not result in any effects in the opposite direction. So by introducing any component in the system the flow path length and the resistance to flow are indirectly increased. So the increase of back pressure is inevitable unless the increase in magnitude compensated in the design of the component itself. The exhaust gas has to pass through the water, which is filled in the scrubber tank. In any case, the outlet from the engine shall be kept below the water level in the scrubber tank for that the gas will pass through the water. The gas has no to push the water, in order to bubble through the water.

The gas has to push the water, in order to bubble through the water in the scrubber tank. This may create chances to increase the backpressure. The baffles, which are provided to deflect the exhaust gases, also offer resistance to the flow and in turn increase the back, pressure. Due to the high temperature, the exhaust gas is let out from the engine, some of the water particles which come in contact, readily changes its phase from liquid state to gaseous state i.e., Steam which increases the net mass of the exhaust gas flow per unit time. The resultant may increase the backpressure.

The lime stone container is used to store the limestone and offers a definite and increased resistance to flow, which again contributes to the increase of backpressure. The limestones are originally intended to reduce the toxic ingredients of the exhaust, gas through chemical reaction. It is evidently affected the flow of resistance and hence the combustion characteristics of the engine will finally contribute the increased toxic ingredients of the exhaust gas. Because of the introduction of the scrubber, the net length of the exhaust gas flow path is also increased which is again against the original intention.

So, all the above factors contribute for the increased backpressure of the system, the system has to be so designed or constructed to reduce the above increase of pressure to its original intended value or original designed value of the engine exhaust system. This could be in principle, accomplished by so many ways. Basically, the elimination of a separate silencer will have way solve the problem, because the scrubber tank, it will act as a silencer and hence the resistance offered by a separate silencer, which is eliminated totally. The introduction of the bell-mouth assembly facilitates the exhaust gas to expand many times by volume gradually before it is coming in contact with the water in the scrubber tank.

CONSTRUCTIONAL FEATURES

Basically an aqua silencer consists of a perforated tube which is installed at the end of the exhaust pipe. The perforated tube may have holes of different diameters. The very purpose of providing different diameter hole is to break up gas mass to form smaller gas bubbles the perforated tube of different diameter .Generally 4 sets of holes are drilled on the perforated tube. The other end of the perforated tube is closed by plug. Around the circumference of the perforated tube a layer of activated charcoal is provided and further a metallic mesh covers it. The whole unit is then placed in a water container. A small opening is provided at the Top of the container to remove the exhaust gases and a drain plug is provided at the bottom of the container for periodically cleaning of the container. Also a filler plug is mounted at the top of the container. At the inlet of the exhaust pipe a non-return valve is provided which prevents the back flow of gases and water as well.

WORKING PRINCIPLE

As the exhaust gases enter in to the aqua silencer, the perforated tube converts high mass bubbles in lo low mass bubbles after that they passes through charcoal layer which again purify the gases. It is highly porous and possess extra free valences so it has high absorption capacity. After passing over the charcoal layer some of the gases may dissolved into the water and finally the Exhaust gases escape through the opening in to the atmosphere. Hence aqua silencer reduces noise and pollution. Following chemical reactions takes place in aqua silencer: Chemical Reaction 1 The obnoxious product of combustion is NOX – the oxides of Nitrogen. Water will absorb the oxides of Nitrogen to a larger extent. The following chemical reaction will enhance the proof, for the above statement.

NO2 + 2H2O 2 HNO2 + 2HNO3 (Diluted) ………..I

Chemical Reaction 2

If a small amount of limewater is added to scrubber tank, further reaction takes place as below.

Ca (OH) 2 + 2HNO2 Ca (NO2)2 + 2H2O

Ca (OH) 2 + 2HNO3 Ca (No3)2 = 2H2O ………..II

Chemical Reaction 3

When the carbon-di-oxide present in the exhaust gas comes in contact with the limewater, calcium carbonate will precipitate. The calcium carbonate when further exposed to carbon-dioxide, calcium-bi-carbonate will be precipitated. The following is the chemical reaction,

Ca (OH) + CO2 CaCO3 = H2O

CaCO3 + H2O + CO2 Ca (HCO3)2 ………..III

Chemical Reaction 4

The sulphur-di-oxide present in the Diesel Exhaust also reacts with the limewater. But the small trace of sulphur-di-oxide makes it little difficult to measure the magnitude of the chemical reaction, accurately. The following equation gives the chemical reaction and calcium sulphite will precipitate.

Ca (OH) 2 + SO2 CaSO3 + H2O …………IV

From calcium carbonate, calcium sulphite will precipitate and CO2 will be by-product. Because of the small percentage and SO2 presence, the liberation of Carbon dioxide is very less. But the liberated CO2 will again combine with CaCO3 to form calcium bicarbonate.

Merits

• No vibration when the engine is running.

• Start the engine easy.

• Control emission and noise in greater level.

• Carbon is precipitated.

Demerits

• Lime water filling is required once in a year

• Silencer weight is more comparing to conventional silencer.

• Additional space is required.

CONCLUSION

The aqua silencer is more effective in the reduction of emission gases from the engine exhaust using perforated tube, lime water and charcoal by using perforated tube the back pressure will remain constant and the sound level is reduced. By using perforated tube the fuel consumption remains same as conventional system by using water as a medium the sound can be lowered and also by using activated charcoal in water we can control the exhaust emission to a greater level. The water contamination is found to be negligible in aqua silencer. It is smokeless and pollution free emission equivalent to the conventional to the silencer. It can be also used both for two wheelers and four wheelers and also can be used in industries.

BIBLIOGRAPHY

1) “Developments of Emission and Noise Control Device”, International Journal of Modern Trends in Engineering and Research,Vol.02,Issue 01

2) K. Kannan & M. Udayakumar, (October 2009) “NOx and HC Emission Control Using Water Emulsified Diesel in Single Cylinder Diesel Engine”,ARPN Journal of Engineering and Applied Sciences,Vol.4, No 8

3) Design And Development Of Aqua Silencer For Two Stroke Petrol Engine ”,International Journal of Innovative Research in Science & Technology Vol. 1, Issue 1, June 2014

4) Guromoorthy S. Hebbar & Anantha Krishna Bhat, (July-Aug. 2012) “Diesel Emission Control by Hot EGR and Ethanol Fumigation; an Experimental Investigation”, International Journal of Modern Engineering Research, Vol.2, Issue.4, pp-1486-1491

5) http://aquapowerltd.com