Formula One Racing Car Technologies | Seminar Report for B.Tech Mechanical Students

Formula One Racing Car Technologies | Seminar Report for B.Tech Mechanical Students

The modern era of Formula One (F1) Grand Prix racing began in 1950, but the roots of F1 trace back to the pioneering road races in France in the 1890s.

At the birth of racing, cars were upright and heavy, roads were tarred with sand or wood, reliability was problematic, drivers were accompanied by mechanics, and races – usually on public roads from town to town – were impossibly long by modern standards. The first proper motor race, staged way back in 1895, was that between the cities of Paris and Bordeaux and the distance between them was 1,200 km.

In 1908, the Targa Florio in Sicily saw the appearance of “pits”, shallow emplacements dug by the side of the track, where mechanics could labour with the detachable rims on early GP car tires. In 1914, the massive 4 ½ liter Mercedes of Daimler-Benz dominated the French Grand Prix at Lyons – 20 laps of a 23.3-mile circuit – taking the first three places and introducing control of drivers by signal from the pits. After this, the Italian racing car manufacturers (like Bugatti and Fiat) dominated for more than a decade.

But the great depression of 1930 led to lack of finances and henceforth, a lack of interest in car racing. In 1934, the balance of power in racing would begin to shift from Italy to Germany, with the emergence of factory teams from Auto Union (now Audi) and Mercedes-Benz, behind massive financial support from the Third Reich government on orders from Adolph Hitler. These powerful and beautiful German machines introduced aerodynamics into Grand Prix car design and ran on exotic, secret fuel brews.

Wings, Shunts and Ground Effects

Formula One technology developed at a furious pace in the 1970s and early 1980s, as F1 designers mastered the art of making airflow work to produce down force. The introduction of wings (or “aero foils”) was made mid-way during the 1968 season. Borrowed from Jim Hall’s revolutionary Can-Am Chaparral, wings allowed for the creation of “down force”, pinning cars to the track for greater traction and vastly increased cornering speed. Although the Cosworth engine was by now ubiquitous in F1, the Lotus 72 – with its distinctive “shovel” nose and nose wings – was significantly faster.

Ferrari returned to the forefront of F1 in 1975 with the flat-12 powered 312T and drivers Niki Lauda and Clay Regazzoni. Formula One cars now sported huge air boxes behind the cockpits to increase air flow to the engine, leading the way (after a short experiment with the famous six-wheel Tyrell P34, which was a front-runner throughout 1976) to the next major technical revolution in F1: ground effects. Formula One engineers, now referred to as “designers”, had been steadily working on aerodynamics for more than a decade. The zenith of the art may have been reached in 1978 with the “ground effects” Lotus 78/79. Ground effects turned the entire car into a large, inverted wing, using side skirts and underbody design to literally glue the car to the circuit.

Mario Andretti who took the Lotus to the championship in 1978, explained that ground effects made the race car “feel like its painted to the road.” Despite their advances, ground effects had a problem, namely that slight miscalculations in set-up would render the ground-effect F1 car undriveable and wickedly unstable. The need to keep ground clearances extremely low led to rigidly sprung, rock-hard cars with virtually no ride height tolerance and little if any ability to handle bumps and curbs. Something really terrible, unnatural and unpredictable would happen if the airflow beneath the car were disrupted for one reason or another. Hence, due to these reasons and also in an effort to bring more driver control and skill to F1, ground effects – first the skirts (along with six-wheeled and four-wheel drive cars) in 1981, and then underbody venture tunnels in 1983 – were finally banned from Formula One car racing, which brought a premature end to an era.

Theory

Aerodynamics is the study of airflow over and around an object, and thus an intrinsic consideration in racing car design. To be quick, a car has to be able to overcome drag (the resistance experienced as it travels forward) and it attempts to do this be presenting the smallest frontal area possible. However, that same car also needs to be able to go around corners and this presents a differing set of aerodynamic needs, namely downforce, which is the force harnessed from the airflow over a car that presses it down onto the track.

The simplest inventions are often the best, and never has the role of aerodynamics proved as dramatic as when aero foil wings burst onto the Grand Prix scene in the late 1960s. These were added in an attempt to provide downforce that gave cars superior traction, and thus made them less likely to spin when being driven around a corner, enabling them to turn at greater speed.

The designers who applied aerofoil weren’t striking new ground, for the technique had long been harnessed in aviation. However, whereas aeroplanes use their wings to gain lift, the Formula 1 designers wanted the reverse, that is to say negative lift, also known as a downforce. This was attained by fitting an aeroplane wing shape upside down. Seen in profile (fig 2.1), an aerofoil leads with its fat edge, but differs from an aeroplane wing in that the trailing edge curves up to the rear, with the airflow over this helping to force the wing downwards.

However, engineers are always faced with a trade-off between maximum downforce and minimum drag, and it’s something that varies from circuit to circuit. The need for downforce is at its greatest at circuits with many corners, such as Monaco, and the need is least at those with the longest straights such as Monza. However Monza circuit is now replaced by a different circuit this year.

Lotus boss, Colin Chapman, took matters a stage further by mounting the rear aerofoil onto the rear suspension of his cars, making the harnessing of downforce all the more effective, as it produced 180 kg of extra downforce, which is the equivalent of more than two adult males. So, it wasn’t surprising that suspension has to be toughened up after a number of breakages.

The slick tires arrived in 1971, with their superior grip meaning that less downforce was required, giving the designers yet another variable to accommodate. Typically, it was Chapman who came up with the next breakthrough in 1977. Although he didn’t invent ground effect – a concept that created a vacuum under the cars that sucked them down to the track and provided extra downforce without extra drag – he was the one to introduce it to Formula 1.

Chapman and his design team found that by putting side pods onto the car (fig 2.2) and shaping their undersides like aerofoil, then sealing the side pod edges to the track surface with moveable skirts, and thus preventing air flowing in from the sides, this would produce an area of low pressure by accelerating the air through a venture at the rear. Sucked down by this low pressure, a car would experience a huge amount of extra downforce, which saw the Lotus 78 setting new standards in aerodynamic efficiency.

Mario Andretti used a Lotus 79 – a car developed from the 78 that he often described as “being painted to the road” – to dominate the 1978 World Championship. By 1980, the downforce generated had blossomed to the equivalent of double the car’s weight. On top of this gain, the faster the cars were driven, the greater amount of downforce their ground effect found them. With downforce increasing as the square of speed, if a car’s speed doubles, then its downforce quadruples. Put another way, a Formula 1 car could run through a tunnel upside down, held to the roof of the tunnel (fig 2.3), thanks to its inverted wings holding it there.

Then ground effects were banned for 1983 and a rule was introduced stating that all cars should have flat bottoms, again altering the emphasis on front and rear wings. So, as Formula 1 entered the 21st century, the designers were poised at their computers dreaming up ways in which they can change their aerofoil to achieve more for less. That is to say more downforce for less drag, the eternal quest for aerodynamicists.

Designing

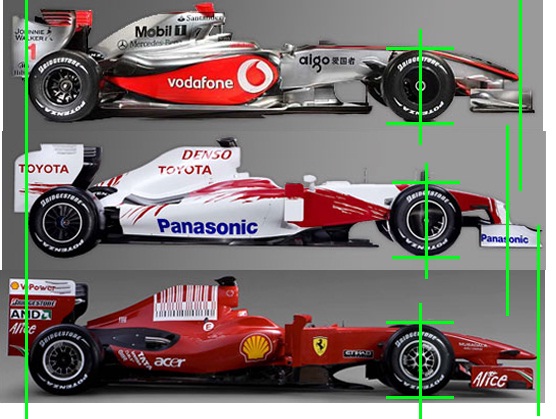

The difference between Ferrari and McLaren is so remarkable, that one may raise some question about the aerodynamics. It is very remarkable that in comparison some cars chose to have a raised nose cone while others a lowered nose cone. Ferrari is one of the example which choose to keep a lowered nose cone. Here’s an explanation.

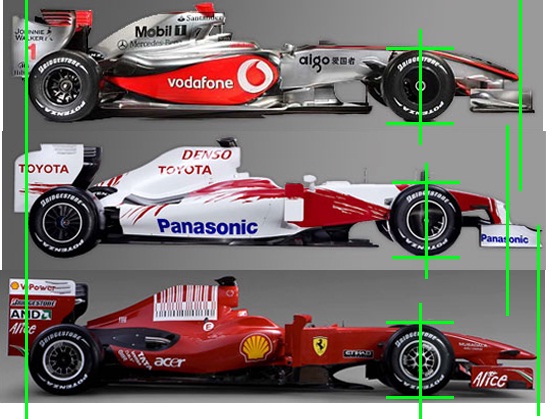

McLaren for example had raised the nose corn. All the changes to the F1 nose parts are due to the regulation change about the front wing, which is placed 5cm higher above the ground .with it ,there has been lost a lot of downforce on the front wheels .Although it might seems very strange that McLaren raised the nose corn for this ,but it makes a lot of sense .As most teams heightened up the nose corn ,it is the most striking ,also because Newey can be seen as a reference .The reason for it is the air flowing under the nose .Of course ,the upper air flowing over the nose generates now less downforce ,but Newey certainly thought it wouldn’t have a very high impact on itself. So the air under the nose is pushed(over the front wing) or pulled(for air coming under the front wing) to higher levels. As the air has a lot more room under the nose in the center of the car , it can be directed to the sidepods smoothly ,it causes a lot less resistance. This can be seen in fig 2.4..

Ferrari on the contrary(fig 2.5) have opted for a completed other tactic . They did not feel maintaining the front wing efficiency as a priority ,although downforce on the front wheel is very important .So the most appropriate solution is the lower nose cone .Exactly what Ferrari did, though with some changes. Thanks to the low nose top ,much air that would not have any effect of the front wheel is very important .So the most appropriate solution is the lower nose cone .Exactly what Ferrari did through with some changes .Thanks to the low nose top ,much air that would not have any affect of the frontwing is now flowing over the nose ,with a lot of downforce as result. The underside of the nose, which seemed to be the most difficult problem with other teams, is solved with a curve. Passing the front wing, and going 30 cm further ,the nose cone at that height could also be the one of a high nose .Once air has passed under the low nose top ,it can be pushed up by the front wing ,without an obstacle. Once the airflow has passed this stadium, lots of downforce has been generated, and the air is guided to the sidepods exactly the same way as with high nose cones. This might be the ingenious design of Ferrari, in which all other teams failed

Comparison of different F1 Cars

Rear wings

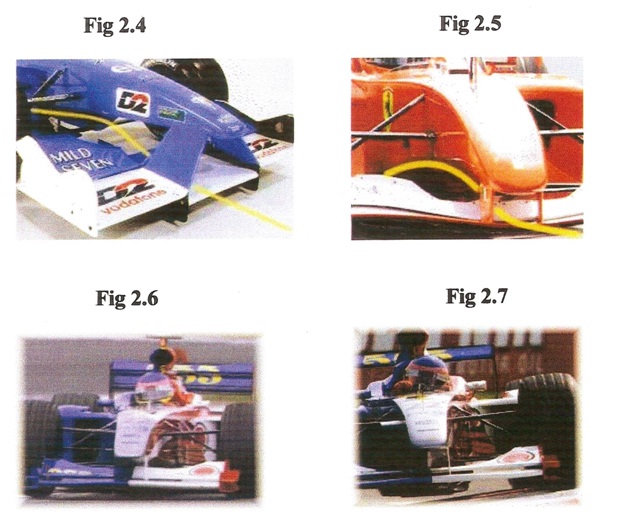

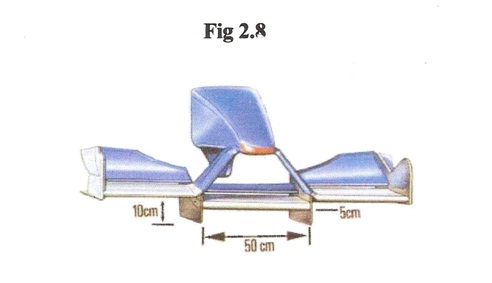

About a third of the car’s total downforce can come from the rear wing assembly. The rear wings are the ones that are varied the most from track to track. As the rear wings of the car create the most drag the teams tailor the rear aerodynamic load to suit a particular track configuration. As air flow over the wing, it is disturbed by the shape, causing a drag force. Although this force is usually less than the lift or downforce, it can seriously limit top speed and causes the engine to use more fuel to get the car through the air. From the year 2009, the FIA regulations have changed concerning the rear wing. What FIA wanted was to reduce the wake and aerodynamic sensitivity of the car and to increase the ability of overtaking and slipstreaming. The solution is by using a High, Squat rear wing. Looking at the cars from only 5 years ago, the also had only 3 or even less flaps. The only effect that might come with this regulation change is at high downforce circuits, there will be a little more air resistance to produce the same downforce and overtaking would be much easier. Perhaps the most interesting change, however, is the introduction of ‘moveable aerodynamics’, with the driver now able to make limited adjustments to the front wing from the cockpit during a race. However, the rear wings can be changed after each race according to the situation and within the specifications mentioned in F1 regulations. Fig 2.6 and 2.7 shows cars using different wings for different circuits.

Engines

The formula one (F1) engine is the most complex part of the whole car. With an amazing horsepower production and about 1000 moving parts, this sort of engine makes the greatest cost on a F1 car. Incredible revolutions of about 17,000 rpm and extreme high temperatures make it very hard to make that engine reliable. This table shows current FIA limitations concerning an engine.

Only 4-stroke engines with reciprocating pistons are permitted.

Engine capacity must not exceed 2400 cc.

Crankshaft rotational speed must not exceed 18,000rpm

All engines must have 8 cylinders arranged in a 90º “V” configuration and the normal section of each cylinder must be circular.

Supercharging is forbidden.

Engines must have two inlet and two exhaust valves per cylinder..

At the moment, all engines have 10 cylinders and they produce about 750 to 850 bhp. These are made from forged aluminium alloy, and they must have no more than four valves per cylinder. Some other parts are made from ceramics because of their very light weight and because they are very strong in the direction they need to be. This very low weight ratio is important to reduce the fuel consumption and increase the engine performance.

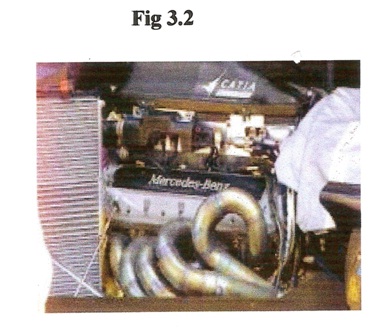

The 1998 Mercedes-Benz engine was possibly one of the most revolutionary engines ever built. Ford started this year by producing an engine that weighted at least 25kg less than any other engine. The stiffness of the engine is also very important because it’s the only connection with the rear wheels and the chassis. The engine must be able to take the huge cornering loads and aerodynamic forces from the large rear wing. The picture in the next page (fig 3.1) shows the Mercedes-Benz engine built by Ilmor engineering and the latest Renault engine.

What makes these engines different from all others?

There are many differences between racing and road car engines that contribute to the large power difference. F1 engines are designed to revolve at much higher speed than the road units. These extreme high revolutions make it impossible for this kind of engine to work as long as a normal car engine. An increase of 50% on revs does not necessarily mean an increase of power with 50%. From a certain point, e.g. 16,500 revs/min, The internal friction is that high that engine power doesn’t increase with a higher rev and even maybe decreases. That shows the importance of the materials that are used. An increase of revs means an increase of internal resistance of material within the engine. Lesser the weight of these materials, lesser would be the power used only for the movement of engine parts.

Exotic materials such as ceramics may be used to reduce the weight and strength of the engine. Because of the very high cost of the materials like these ceramics and carbon fiber, they are not used in usual cars. Most usual car engines are made from steel or aluminium. Another deciding point trying to reach a maximum of power out of an engine is the exhaust. The minor change of length or form of an exhaust can influence the horsepower drastically. Exhaust are important to remove the waste gases from the engine. The faster these gases are moved away from the engine, the faster some kind of vacuum comes in the engine and the more air is sucked into it. This causes a faster cool down or more power from the engine with the same fuel consumption.

Automatic changed length of height from the exhaust could make so quite a big power advance. Unfortunately, these types of advanced exhausts are completely forbidden by the FIA. Just above the driver’s head there is a large opening that supplies the engine with air. It is commonly thought that the purpose of this is to ‘ram’ air into the engine like a supercharger, but the air-box does the opposite. Between the air-box and the engine there is a carbon-fibre duct that gradually widens out as it approaches the engine. As the volume increases, it makes the air flow slow down, raising the pressure pressure of the air which pushes it into the engine. The shape of this must be carefully designed to both fill all cylinders equally and not harm the exterior aerodynamics of the engine cover.

Transmission

An amazing engine may be one thing, but how do you put all the power on the ground without wasting it by wheel spin is another. The transmission is made the same way and with the same principle as a normal transmission but there are some capital differences. The weight for example, the height from the ground and the size are the most logical. But thinking that a transmission can be as hot as 1000C when the power is brought to the wheels at the start of each race is certainly very important for the engineers. Each team builds their own gearbox, either independently or in partnership with companies such as X-track. The regulations state the cars must have at least 4 and no more than 7 forward gears as well as a reverse gear. Most cars have 6 forward gears, some having a 7-speed gearbox. Continuously Variable Transmission (CVT) systems are not allowed and cars may have no more than two driven wheels. Transmissions may not feature traction control systems, nor devices that help the driver to hold the clutch at a specific point to aid getaway at the start of the race.

Because the gearbox carries together with the engine the whole rear car weight, it has to be very solid and strong, and so it is normally made from fully-stressed magnesium or new since 1998, introduced by Stewart and Arrows, from carbon fibre, which is much lighter. Gear cogs or ratios must be made of steel and are used only for one race, and are replaced regularly during the weekend to prevent failure, as they are subjected to very high degrees of stress. The gearbox is linked directly to the clutch, made from carbon fibre. Two manufacturers, AP racing and Sachs produce F1 clutches, which must be able to tolerate temperatures as 500 degrees. The clutch is electro-dynamically operated and can weigh as little as 1.5 kg. A computer, taking between 20-40 milliseconds, controls each gear change. The drivers do not manually use the clutch apart from moving off from standstill, and when changing up the gears, they simply press a lever behind the wheel to move to the next ratio.

CONCLUSION

As Formula One racing enters the new era, the focus has now shifted from achievement of high speed and acceleration levels to enhancement of driver safety. The sport’s governing body, FIA has already taken measured steps to slow down the car, and also reduce inclination towards the technologies so that races can be won merely on the basis of driver’s skills. This being easily the most money-generating sport, every year more and more teams are attempting to get into it in spite of the high initial costs involved. Thus the global appeal for this sport is enormous, with the sport now having spread its tentacles from Europe to almost every nook and corner of the world including India. With the introduction of newer technologies like traction control and semi-automatic gearboxes, along with the use of diffusers and slick tyres, the sport has become more attractive than ever.

REFERENCES

1. Climate change and KYOTO Protocol’s, clean development mechanism by M. Orford, S.Raubenheimer, Barry Kantor.

2. Green wealth by Kevin Francis Noon.

3. Emissions trading principles and practice by Thomas H Tietenberg.

4. From Wikipedia, the free encyclopedia.

5. http//www.preserval.com