Floating Windmills | Seminar Report for B.Tech Mechanical Students

Floating Windmills | Seminar Report for B.Tech Mechanical Students

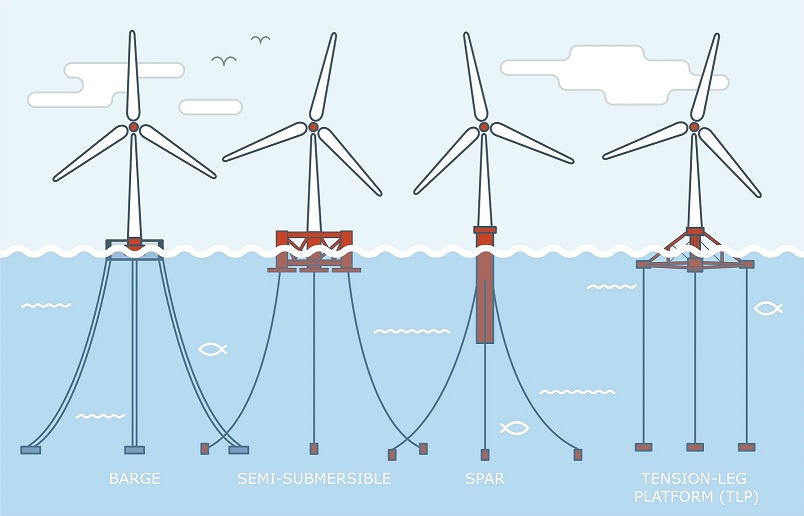

A floating wind turbine system with a tower structure that includes at least one stability arm extending there from and that is anchored to the sea floor with a rotatable position retention device that facilitates deep water installations.

Variable buoyancy for the wind turbine system is provided by buoyancy chambers that are integral to the tower itself as well as the stability arm. Pumps are included for adjusting the buoyancy as an aid in system transport, installation, repair and removal. The wind turbine rotor is located downwind of the tower structure to allow the wind turbine to follow the wind direction without an active yaw drive system.

The support tower and stability arm structure is designed to balance tension in the tether with buoyancy, gravity and wind forces in such a way that the top of the support tower leans downwind, providing a large clearance between the support tower and the rotor blade tips. This large clearance facilitates the use of articulated rotor hubs to reduced damaging structural dynamic loads. Major components of the turbine can be assembled at the shore and transported to an offshore installation site.

INTRODUCTION

A floating wind turbine is a wind turbine mounted on a floating structure that allows the turbine to generate electricity in water depths where bottom-mounted towers are not feasible. The wind can be stronger and steadier over water due to the absence of topographic features that may disrupt wind flow. The electricity generated is sent to shore through undersea cables. The initial capital cost of floating turbines is competitive with bottom-mounted, near-shore wind turbines while the rate of energy generation is higher out in the sea as the wind flow is often more steady and unobstructed by terrain features.

The relocation of wind farms into the sea can reduce visual pollution if the windmills are sited more than 12 miles (19 km) offshore, provide better accommodation of fishing and shipping lanes, and allow siting near heavily developed coastal cities. Floating wind parks are wind farms that site several floating wind turbines closely together to take advantage of common infrastructure such as power transmission facilities.

Need For Floating Windmills

A few hundred meters offshore, winds are twice as strong as on land in much of the world. Offshore wind energy has huge potential, and floating wind turbines is a promising technology. Such turbines are now being developed. They are meant to be used out at sea in deep waters, and they do not need to be permanently moored to the ocean bed. DEEP SEA. Criteria for location of an offshore wind farm is excellent wind conditions and suitable water depth. The wind farm must be situated near a strong onshore power grid and near harbours and shipyards.

Energy is a major factor in today’s society

Alternative fuel and alternative energy resources are in great demand

Most everyone in the world is looking for more energyefficient ways to live

Hybrid vehicles and other fuel-efficient technology is arising around the world

The world has to change, this emergency that we are experiencing today should have been taken care of long before now.

Now we have no choice but to develop new technology in very little time

Design Consideration:

Central receiver (or power tower) systems use a field of distributed mirrors – heliostats – that individually track the sun and focus the sunlight on the top of a tower.

By concentrating the sunlight 600–1000 times, they achieve temperatures from 800°C to well over 1000°C.

• The central receiver is also called high-tech heat exchanger which sits atop a tower. The central receiver heats molten salt at around 250°C, pumped from a “cold” storage tank, to 565°C, where it flows to a “hot” tank for storage.

• When the grid load dispatcher decides electricity is needed from the plant, hot salt is pumped to a steam generating system that produces superheated steam for a turbine/generator.

• The salt then is returned to the cold tank, where it is stored and eventually reheated in the receiver to complete the cycle.

• Smaller, simpler receivers are needed to improve efficiency and reduce maintenance. Advanced receiver development currently underway, under the SolMaT Initiative, includes consideration of new steel alloys for the receiver tubes and ease of manufacture for the entire receiver subsystem. Panels of these new receiver designs were initially tested at Solar Two.

Energy Production From Windmills

1. The wind blows on the blades and makes them turn.

2. The blades turns a shaft inside the nacelle (the box at the top of the turbine)

3. The shaft goes into a gearbox which increases the rotation speed enough for…

4. The generator, which uses magnetic fields to convert the rotational energy into electrical energy. These are similar to those found in normal power stations.

5. The power output goes to a transformer, which converts the electricity coming out of the generator at around 700 Volts (V) to the right voltage for distribution system, typically 33,000 V.

6. The national grid transmits the power around the country.

Instruments to measure the wind speed and direction are fitted on top of the nacelle. When the wind changes direction motors turn the nacelle, and the blades along with it, around to face the wind. The nacelle is also fitted with brakes, so that the turbine can be switched off in very high winds, like during storms. This prevents the turbine being damaged. All this information is recorded by computers and transmitted to a control centre, which means that people don’t have to visit the turbine very often, just occasionally for a mechanical check. This is often done by local firms.

Advantages:

Compared to other energy sources, windmills are very kind to the enviroment. Compared to power stations driven by coal they will save the enviroment for:

· Carbon dioxide (CO2) 850,0g

· Sulphur dioxide (SO2) 2,9g

· Nitrogen dioxide (NO2) 2,6g

· Dust 0,1g · Cinders, and flying ashes 55,1g

The brand new windmills are today so competitive on good places, that the use of windmillpower is one of the cheapest methods to reduce the emission of CO2 from the production of electrisity. Windmills have no form of emissions of gases and other harmful substances. The wind which tries to press the blade speed a little longer up causes the generator to start producing power on the net. When the speed of the wind has reached windpower at 13-15 m/s the mill grants on its maximum at 500 kw for a 500 kw mill.

Disadvantages

Windmills are tall and they stand on places were the terrain is very open and free. Therefore there is also free outlook to the windmills. If the windspeed has reached its maximum the mill is forced to reduce speed to not hurt the mills’ machinery. It is a disadvantage that the windmills don’t have an engine with a greater capacity. The technology we use on windmills is very valuable and advanced, therefore the government hesitates to exploit wind power. As shown on the drawing below , you can see that this is advanced technology.

Floating Windfarms Vs Oil and Gas Reservoirs

1 Barrel of Oil ~ 130 kg ~ 1.5 MWh of Energy (~ 12 kWh / kg)

1 MW of Rated Wind Turbine Power @ 40% Capacity Factor ~ 9.6 MWh / Day ~ 6.4 Barrels of Oil / Day

Conversion Efficiency of Oil & Gas Engines / Turbines, Wind Turbines ~ 40-50%

1 GW Wind Farm (30 year life) ~ 70 M Barrel Oil Field ~ 6,400 Barrels / Day

Breakeven Cost of Wind Turbines $3M / Rated MW = $3 B / Rated GW

Equivalent Cost per Barrel of Oil ~ $43 / Barrel

Investment Risk in Oil & Gas: Exploration Costs & Volatility of Oil & Gas Prices

Investment Risk in Wind: Volatility of Wind Speed & Electricity Prices.

CONCLUSION

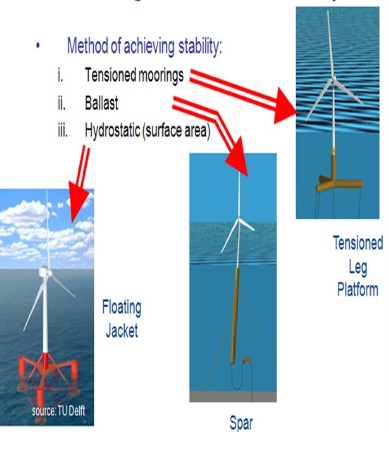

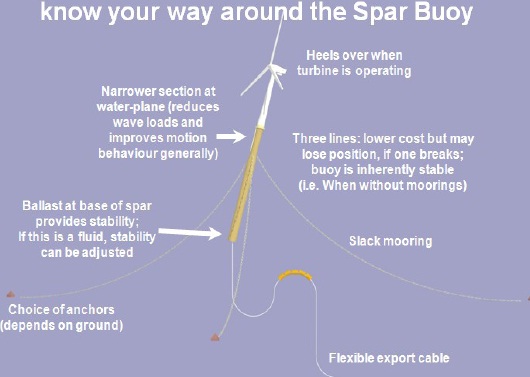

Optimized Spar Buoy and TLP Wind Turbine Floaters

Low Responses – Use of Onshore Wind Turbines

Hybrid Offshore Wind & Wave Farms

Optimal Control to Enhance Wind and Wave Power Output

Design of Offshore Electric Grids

Attractive Economic Attributes

Project Finance for Utility Scale Offshore Wind & Wave Farms

BIBLIOGRAPHY

Musial, W.; S. Butterfield, A. Boone (2003-11). “Feasibility of Floating Platform Systems for Wind Turbines”. NREL preprint (NREL) (NREL/CP-500-34874): 14. Retrieved 2009-09- 10.

Mark Svenvold (2009-09-09). “The world’s first floating wind turbine goes on line in Norway”. DailyFinance.com. Retrieved 2009-10-20.

Union of Concerned Scientists (2003-07-15). “Farming the Wind: Wind Power and Agriculture”. Retrieved 2009-10-20.