Electricity Generating Shock Absorber | Seminar Report for B.Tech Mechanical Students

Electricity Generating Shock Absorber | Seminar Report for B.Tech Mechanical Students

Road vehicles can expend a significant amount of energy in undesirable vertical motions that are induced by road bumps, and much of that is dissipated in conventional shock absorbers as they dampen the vertical motions.

An electromagnetic linear generator and regenerative electromagnetic shock absorber is disclosed which converts variable frequency, repetitive intermittent linear displacement motion to useful electrical power.

The innovative device provides for superposition of radial components of the magnetic flux density from a plurality of adjacent magnets to produce a maximum average radial magnetic flux density within a coil winding array. Due to the vector superposition of the magnetic fields and magnetic flux from a plurality of magnets, a nearly four-fold increase in magnetic flux density is achieved over conventional electromagnetic generator designs with a potential sixteen-fold increase in power generating capacity.

As a regenerative shock absorber, the disclosed device is capable of converting parasitic displacement motion and vibrations encountered under normal urban driving conditions to a useful electrical energy for powering vehicles and accessories or charging batteries in electric and fossil fuel powered vehicles. The disclosed device is capable of high power generation capacity and energy conversion efficiency with minimal weight penalty for improved fuel efficiency.

INTRODUCTION

We have been carrying out a proof-of-concept study to evaluate the feasibility of obtaining significant energy savings by using optimized regenerative magnetic shock absorber in vehicles. In addition to other potential applications, the use of such shock absorbers might allow for improved energy efficiency in electrical vehicles through the conversion of otherwise parasitic mechanical power losses into stored electrical energy, thereby leading to longer distances between battery recharges.

We recently carried out two experiments that validated a simplified eddy current damping model which, together with a “road bump” model (discussed further below), has been used to estimate the average power/energy recovery that might accrue for a 2500 lb automobile travelling on a “typical” road in the United States. The estimates are summarized in Table 1, and suggest that with a set of optimized regenerative shock absorbers, the average vehicle on the average road driving at 45 mph might be able to recover up to 70% of the power that is needed for such a vehicle to travel on a smooth

How It Works

A conventional automotive shock absorber dampens suspension movement to produce a controlled action that keeps the tire firmly on the road. This is done by converting the kinetic energy into heat energy, which is then absorbed by the shock’s oil.

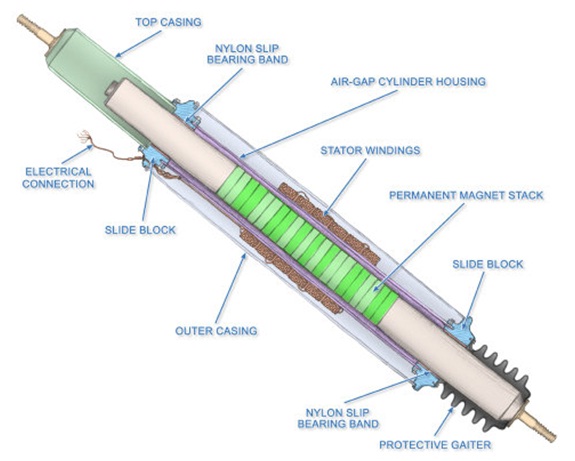

The Power-Generating Shock Absorber (PGSA) converts this kinetic energy into electricity instead of heat through the use of a Linear Motion Electromagnetic System (LMES). The LMES uses a dense permanent magnet stack embedded in the main piston, a switchable series of stator coil windings, a rectifier, and an electronic control system to manage the varying electrical output and dampening load.

The bottom shaft of the PGSA mounts to the moving suspension member and forces the magnet stack to reciprocate within the annular array of stator windings, producing alternating current electricity. That electricity is then converted into direct current through a full-wave rectifier and stored in the vehicle’s batteries.

The electricity generated by each PGSA can then be combined with electricity from other power generation systems (e.g. regenerative braking) and stored in the vehicle’s batteries. In turn, the electrical power can be used to recharge batteries or other efficient energy storage devices (e.g., flywheels) rather than be dissipated

PLUG AND PLAY

The power generating shock absorber is the same basic size and shape, and mounts in the same way, as a standard shock absorber or strut cartridge.

ADJUSTABLE DAMPENING

An electronic control system monitors the requirements of each individual road wheel’s suspension and varies the dampening by quickly switching on or off individual stator coil rings. With all stator coil rings switched on the PGSA produces a strong dampening force which can then be varied for disparate road conditions by switching coils on and off as needed. This provides an added level of benefits in allowing the shock to be very soft in cruising situations (small, high-frequency movements) and instantly change to a sport shock in aggressive cornering situations (longer, lower-frequency movements). Further, the rebound and compression strokes can have different dampening values and application curves depending on performance requirements.

This application could conceivably produce over twenty watts per wheel in normal operation. City driving, with its varying road surface characteristics, as well as stop and go traffic’s font-to-back loading, will generate more power than driving on smooth roads at consistent speeds.

MANUFACTURING CONSIDERATIONS

Manufacture of the Power-Generating Shock Absorber will require a machined main shaft with embedded permanent magnet stack, a strong air-gap cylinder housing, high quality stator windings, and robust slide bearings.

Other systems, such as microprocessor-controlled voltage, current, and dampening regulation, external casing, protective bellows, etc. will also need to be designed and tested.

APPLICATIONS

LMES technology is already finding its place in ocean power generating systems.

Its introduction into the automotive world is the next logical step.

This technology can be applied to any type of vehicle that employs movable suspension technology and uses electricity in some form as its fuel.

ADVANTAGES

Shock absorbers have a great for performance, handling and stability.

They are best choice for work and severe use vehicles.

High pressure gas mono tube design- 360psi to prevent aeration and shock fade. These have a lighter valving than the heavy duty units.

Low pressure gas twin tube design- These units are good for average, everyday driving and a very good replacement for OE units.

The “electricity generating suspension system” has a much higher energy yield than other known invention

Disadvantages

Complexity

Problem occurred in collecting materials.

Time consuming.

Found some drawbacks of suspension system like rubbing in (LWV) light weight vehicles.

In case of Induction Brakes, whole system can undergo failure because of electric motor.

As whole system consist electric wiring so this may occur short circuit of system.

This system consist a speed limit up to 35 km/h.

CONCLUSION

Conventionally, the vibration energy of vehicle suspension is dissipated as heat by shock absorber, which wastes a considerable number of resources. Power Generating Shock Absorber brings hope for recycling the wasted energy. All types of Power Generating Shock Absorber, especially electromagnetic suspension, and their properties are reviewed in this seminar. From the perspective of comprehensive performance including vibration control ability, regenerative efficiency and application reliability, the configuration of hydraulic transmission and self-powered MR damper shows the best attraction. With improvement of technology, Power Generating Shock Absorber may become one of promising trends of vehicle industry.

BIBLIOGRAPHY

1. Kirpal Singh, Automobile Engineering Volume 1, Suspention , page no. 168

2. Horst Bauer (ed)., Automotive Handbook 4th Edition, robert Bosch GmbH 1996, ISBN 0-8376-0333-1page 584

3. Carley, Larry (February 2008), “Monotube shocks– don’t absorb shocks, but…”, Brake and front end magazine, retrieved 1 January 2014

4. Setright, L. J. K. “Dampers: Smoothing Out the Bumps”, in Northey, Tom, ed. World of Automobiles (London: Orbis, 1974), Volume 5.

5. Steve Karamihas, University of Michigan Transportation Research Institute, University of Michigan, private communication ([email protected]).

6. Estimated from General Motors Impact (electrical vehicle) specifications; and from Hugh C.Wolfe, senior editor, “Efficient Use of Energy”, Chap. 4, AIP Conference Proceedings No.25, American

7. Institute of Physics, NY (1975).